PRODUCT INFORMATION

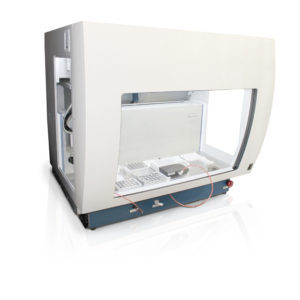

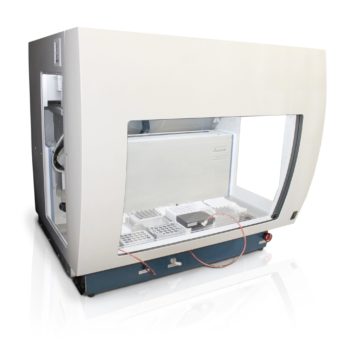

The VERSA Automated SPE System streamlines solid phase extraction, automating cartridge conditioning, sample derivatization, and solvent evaporation for contamination-free sample prep and trace analyte enrichment. Optimized for HPLC, GC-MS, and LC-MS analysis, VERSA enhances efficiency with:

✅ ReagentDrop™ Dispenser – Tip-free reagent dispensing, minimizing contamination.

✅ Heater-Shaker Module – Ensures thorough mixing and temperature control.

✅ Gripper & Nitrogen Dryer – Precise handling and efficient solvent evaporation.

From the compact VERSA 10 to the customizable VERSA 1100, these systems boost productivity in:

🔹 Forensic & Toxicology Testing – Drug and metabolite extraction.

🔹 Environmental & Food Safety – Contaminant analysis.

🔹 Pharmaceutical & ADME Studies – Compound isolation.

Upgrade to VERSA SPE for faster, more reliable extractions. Contact us today to optimize your workflows!

- Food Safety

- Vitamin D from Blood/Serum Samples

- Drugs of Abuse in Forensic Analysis

- Compounds for Drug Discovery

- Iso-flavonoids from Urine Samples

- Aflatoxins from Seafood Products

- Growth Promoters in Blood

- Semi-volatile or Non-volatile Analytes

- Protein Precipitation

Specifications | VERSA 1100 Automated Solid Phase Extraction (SPE) System |

| Deck Capacity | 15 |

| Pipetting Head (Single Channel Function, Disposable Tip) | 4 or 8-channel |

| ReagentDrop | up to 8 |

| Supported Cartridges | 1, 3 or 6 mL cartridges or 96 SPE cartridge plate |

| Gripper | Gripper |

| Pressure Module(s) | 4-channel positive pressure module and/or vacuum manifold (negative pressure) |

| Nitrogen Dryer | 24 or 96 channels |

| Shaker-Heater (2400rpm, RT to 90°C) | Optional |

| Reagent Block Cooler | Optional |

| Liquid Level Sensing | Optional for Liquid-Liquid Extraction |

| HEPA/UV/LED Enclosure | Included |

| Width x Depth x Height (cm) | 99 x 75 x 90 |

| Weight (kg) | 162 |

Independently Validated

Spatial and temporal resolution of metabolic dysregulation in the Sugen hypoxia model of pulmonary hypertension

View the publications

High-Throughput SPE/GC-MS Method for Quantification of Methamphetamine and Amphetamine in Urine Samples of Drug Users

View the validation poster to see how the VERSA 1100 automated Solid Phase Extraction system is eliminating cross-contamination while ensuring accuracy and reproducibility in urine samples of drug users.

Development of an Automated Solid Phase Extraction of Procainamide in Serum Samples

Decrease of Protein Phosphatase 2A Subunit B by Glutamate Exposure in the Cerebral Cortex of Neonatal Rats

Modules Tailored for your Entire Automated SPE Workflow

SPE Cartridge Holder

works with the Gripper to automate conditioning, loading, washing, eluting, and fraction collecting steps

Gripper

moves cartridge block and nitrogen dryer for on-deck washing, elution, drying, and derivatization

Shaker-Heater

allows efficient sample pre-processing and derivatization, streamlines complete automated SPE workflow

Vacuum Manifold (Negative Pressure)

ensures samples and reagents flow through cartridges efficiently

Positive Pressure Module

ensures samples and reagents flow through cartridges efficiently

Nitrogen Dryer

enables on-deck sample drying/concentration prior to reconstitution/derivatization

Reagent Block Cooler

cools reagents for derivatization

ReagentDrop

dispenses reagents from off-deck reservoirs and eliminates tip usage – prevents dripping of volatile solvents

- Capable of performing Automated Liquid Liquid Extraction on the same workstation (VERSA 1100)

- Compatibility with organic and aqueous reagents

- Exhaust system available to remove volatile organic fumes

- HEPA/UV/LED Enclosure – keeps samples contamination-free

- Unparalleled Customer Service – our engineering team is readily available to troubleshoot your protocols

What is the throughput?

It can be configured for 24-sample or 96-well format depending on instrument channels (4 or 8 channel head) – actual throughput time will depend on the specific procedure and steps involved.

Does the instrument come with its own nitrogen supply or does it use the lab’s?

The workstation’s nitrogen dryer has to be connected to the overall lab’s nitrogen supply for any drying step.

What liquids are compatible?

a. For ReagentDrop – most organic solvents are compatible – avoid concentrated aqueous solutions (salting out could clog the tubing) and concentrated acids or bases (can degrade metal components).

b. For pipetting and solutions on deck – avoid very volatile solvents and any concentrated acids or bases (fumes can degrade instrument components).

What is the sample handling volume?

a. Pipette maximum aspiration/dispensing volume is 1000uL.

b. Samples handling is around 10-15 mL.

Can the samples and solvent be kept cool?

Yes, we have cooler/heater flat plates that can bring down the temperature to 4 oC.

What sample sizes/consumables are compatible?

We have custom fabrication/3D printing abilities to meet whatever your needs.

What if my solvent is not compatible with polypropylene pipette tips?

We can offer a steel-pin system (4 or 8-channel, up to 1000 uL) system.

Is barcode tracking available?

Barcode tracking is optional.

What column sizes are compatible with the VERSA 1100 SPE?

Our system can fit 1 mL, 3 mL, and 6 mL SPE cartridges which would then use a positive pressure module, as well as 96-well SPE extraction plates which would use a vacuum system instead of a positive pressure modulator.

Difference between a vacuum system and positive pressure module?

A positive pressure module will be used for conditioning, washing and elution if the samples are processed in cartridge columns. A vacuum system is used if the samples are processed in a 96-well plate.