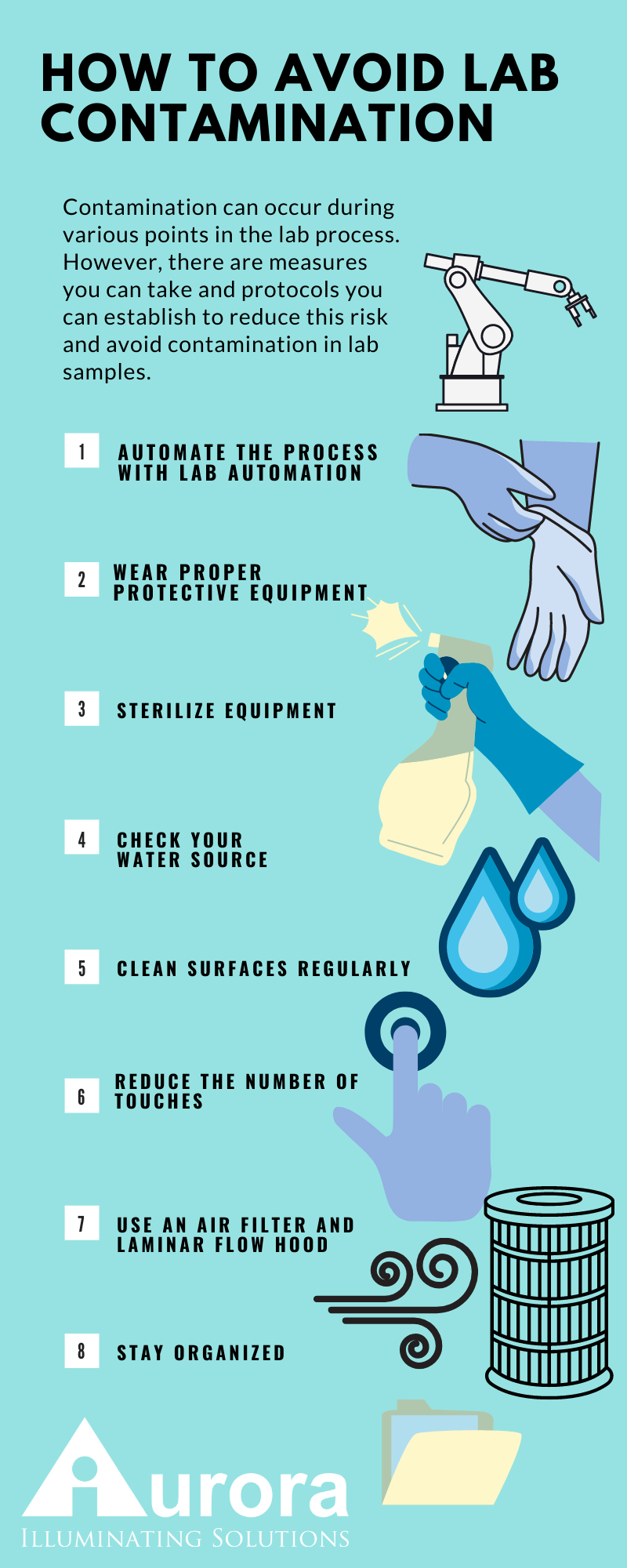

Many factors can affect the outcome of data in a laboratory setting. Perhaps the most common factor is the contamination of lab samples. Contamination can occur during various points in the lab process. However, there are measures you can take and protocols you can establish to reduce this risk and avoid contamination in lab samples.

What is contamination?

Contamination is when an unwanted substance is present. In biological science, this could include unwanted: bacteria, DNA, RNA, protein, plant, or animal. In chemistry, contamination is the presence of unwanted molecules.

How to reduce contamination in the lab

Automate the process

Perhaps the best way to avoid contamination in lab samples is by automating certain aspects of the process. Introducing automated liquid handling equipment into your laboratory can significantly reduce the risk of human error and cross-contamination of samples. You can equip these machines with additional attachments, such as specialized plate types and heater-shakers, to further automate the process. Additionally, the enclosed hood of these machines creates a contamination-free workspace within your laboratory.

For more information regarding the benefits of automated liquid handling and it can help reduce contamination and human error in your lab, check out our helpful beginner’s guide.

Wear proper protective equipment

Regardless of the industry, most labs require individuals to follow certain protocols regarding personal protective equipment. Wearing gloves, hairnets, pants, lab coats, and close-toed shoes. This equipment protects both the person wearing it and reduces contamination. Personnel should never reuse disposable gloves and they should always change them when moving between samples to further reduce the risk of contamination. You can also wear lab only shoes. Take off the shoes you wear outside and wear shoes you only wear in the lab. This reduces outside contaminates.

Clean and sterilize equipment

Maintaining a sterile work environment is crucial to avoiding contamination. Be sure to thoroughly clean and sterilize every piece of lab equipment regularly. For some pieces of equipment, such as glassware, this may be as frequent as every day. For others, it may be dependent on the frequency of use as well as the materials used. Utilizing automated equipment, such as a lab water purification system, can reduce the amount of time spent sterilizing equipment without sacrificing the degree of cleanliness. Make a cleaning schedule of who cleans what equipment when. Keep records of when cleaning occurred. Create standard operating procedures on how to clean the equipment in the lab. This will help train future lab members and ensure cleaning is done the same way each time.

Check your water supply

If all of your samples including your negative control have been contaminated then it could be your water supply. In the lab, deionized water and distilled water are normally used to prevent contamination. However, your machine that makes your purified water may need to be serviced or repaired. Filters should be regularly replaced. You could test your water using an electroconductive meter to see if other chemicals are present. Or you could use general culture media in a petri dish with only your water as a sample to see if anything is alive in the water.

Reduce the number of touches

Human error is a major cause of contamination. Reducing physical touches reduces contamination in two ways; reduces the chance that something is transferred by physical contact and reduces the chance of human mistakes. If you are regularly following the same procedures map out your process on a piece of paper or computer and count the touches. Find ways to reduce the number of transfers and touches.

Use air filters and laminar flow hoods

When you are transferring samples it is critical to work in an environment where the air will not interfere with your sample. You should work in a hood that keeps air moving, preventing microbes in the air from landing. Air filters trap contaminates in the air, keeping your environment sterile. Make sure your air filter has not expired and your flow hood is working properly.

Stay organized

When establishing a protocol for reducing the risk of sample contamination, you may consider reorganizing the laboratory in favor of creating a more directional workflow. Creating a structured workflow within the lab will ensure that everything stays in the proper location, reducing the risk of accidental contamination. Establishing specific areas and designating specific equipment for each step in the laboratory process will reduce the risk of contamination and streamline the process, increasing productivity and efficiency.

Sterile in an open flask

Did you know you don’t need a vacuum to keep something sterile? Imagine leaving fruit juice in a glass and not worrying if it will go bad. That’s exactly what Louis Pasteur did to strengthen a new theory at the time, germ theory.

Before germ theory, the main explanation of why people got diseases was because of bad air. The main explanation of how things rotted was spontaneous generation. Spontaneous generation stated that living things were instantly created from nonliving things under the right conditions.

Where did the rats come from? Spontaneous generation of flour and rags.

Where did flies and maggots come from? Spontaneous generation of an unburied corpse.

Germ theory challenged these explanations. Germ theory explained food rotting and diseases came from small organisms that humans cannot see with the naked eye. Microscopes, a new technology at the time opened people’s eyes to microbes. Germ theory proposed that these microorganisms can then cause disease.

Louis Pasteur was a French scientist, where the word pasteurization comes from. Pasteur experimented to see if life spontaneously generated. The experiment used a swan-necked flask. Pasteur took two bottles of juice and heated them with a flame, sterilizing them. While the flasks were sterile Pasteur bent the neck of one (swan-necked) and clipped the other one. Both flasks were open to the air, however, the one with the swan neck had a bend making microbes in the air unable to fall into the flask. Airborne microbes were able to fall into the other flask with an open face-up hole. After time the juice in the flask with the face-up hole started to rot. The juice in the swan-necked flask did not rot. If spontaneous generation was true then the juice in both flasks should have rotted. Germ theory got one more piece of evidence.

Why do laminar flow hood work?

Laminar flow hoods keep air moving in a workspace so microbes in the air cannot land on the sterile item. Some flow hoods provide extra protection with filters and UV light to reduce contamination even more. UV light kills microbes while air filters are a physical screen, blocking and trapping microbes. HEPA stands for high-efficiency particulate air. HEPA is a standard for air filtration, blocking 99.9% of microbes in the air.

The VERSA series are tools for lab automation. They are automated liquid handlers with built-in HEPA air filters and UV inside their hood. Because the system is automated contamination from human error is eliminated.

What is cross-contamination, cross-contact, direct contamination and cross-infection?

Cross-contamination in food safety is when a pathogen is transferred between foods.

Cross-contamination in biological science is when part of one sample is transferred into another sample.

Cross-contamination in medicine is when a pathogen is transferred from one individual to another.

Final product contamination in the pharmaceutical industry is the product in a version the customer would use has been contaminated with a drug, a pathogen, or toxin.

Cross contact in food safety is when two foods touch and a food allergen is transferred.

Cross infection in medicine is when a pathogen is transferred from one individual to another, infecting the second individual. Cross-contamination is needed to occur first before cross-infection.

Direct contamination in food safety is when a person or surface transfers a pathogen to a food.

The four types of cross-contamination are chemical, microbial, physical, and allergenic.

How to Avoid Lab Contamination

- Automate the process with lab automation

- Wear proper protective equipment

- Sterilize equipment

- Check your water source

- Clean surfaces regularly

- Reduce the number of touches

- Use an air filter and laminar flow hood

- Stay organized

Summary

A lot of contamination is from human error. You can reduce human error by using automated lab equipment. Wear personal protective equipment such as gloves, hairnets, pants, lab coats, and close-toed shoes. Check to make sure your water source is not contaminated. Regularly clear surfaces and lab equipment. Keep a cleaning schedule and document when cleaning has been done. Map out your common procedures and reduce the number of touches. Use air filters and laminar flow hoods. Stay organized.

To learn more about lab automation, contact us.